Post-consumer HDPE-detergent bottles can be recycled into odor-reduced regranulate that can be reused in the same application instead of being downcycled. ©Starlinger

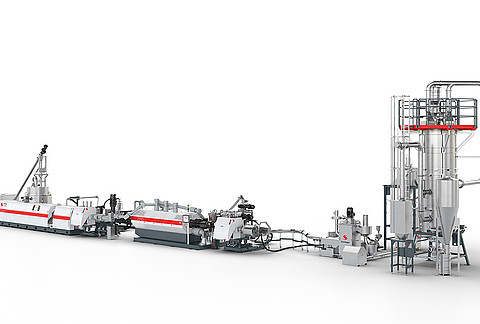

Post-consumer recycling at top level: Starlinger’s new system setup combines a recoSTAR dynamic recycling extruder with the viscoZERO melt phase decontamination reactor and the PCUplus pellet flusher, achieving super-cleaning and odor reduction for PP, PE, PS and PET. ©Starlinger

Solutions for food-grade recycled post-consumer PE, PP, PS and PET at NPE 2024

Super-cleaning and odor reduction solutions for the most popular consumer packaging materials: The two Starlinger business units viscotec and recycling technology have joined forces to offer high-end solutions for producing food-grade recycled PP, PE, PS and PET.

Based on Starlinger’s vision “food-grade without compromise”, the combination of the proven post-consumer pelletizing line recoSTAR dynamic with the new viscoZERO melt phase decontamination technology and the downstream pellet flushing unit PCUplus provides super-cleaning and odor reduction not only for PET but also for PP, HDPE and PS.

“With this new machine setup we present a super-cleaning solution for post-consumer packaging made of polyolefins such as PP and PE or polystyrene at this year’s NPE”, said Paul Niedl, Commercial Head of Starlinger recycling technology. “Especially PP, PS and HDPE post-consumer packaging waste degrades during recycling; thus, the produced material can only be used in lower-grade applications. With the new technology, the material is upgraded in the process and thus suitable for use in high-grade applications including direct food-contact packaging.”

Re-cycling instead of down-cycling

The newly conceived recycling process ensures the thorough decontamination of post-consumer PP, PE or PS food packaging, producing food-safe, odor-reduced regranulate that can be reused in the production of food-contact packaging instead of other, lower-grade types of packaging.

The recycling system consists of a recoSTAR dynamic recycling extruder with/without degassing, a continuous melt filter or power-backflush filter, the viscoZERO melt phase decontamination reactor, a subsequent belt melt filter or power backflush filter before the underwater or waterring pelletizer, and the optional PCUplus pellet flusher at the end of the process. Depending on the components in the line setup, the system produces recycled resin in various grades, ranging from food-safe to highly decontaminated and odor-treated. The viscoZERO reactor in combination with the PCUplus pellet flusher produces recycled PE, PP and PS that meets the highest standards for packaging with direct food contact.

The viscoZERO melt phase decontamination reactor can also be installed as a turn-key stand-alone solution for decontaminating different types of high-viscosity materials fast and efficiently. “The viscoZERO reactor opens new business opportunities as it provides plastics recyclers with the flexibility to process a wide range of input materials into resins of outstanding quality”, said Gerhard Bräuer, Product Manager viscoZERO at Starlinger viscotec. “You can recycle post-consumer PP, PE, PS, and PET and achieve highest output quality for the respective material so that it can be used in food-contact packaging.” During the decontamination process in the reactor volatile contaminants are removed effectively and the material is cleansed and homogenized. Unwanted odors or substances such as spin finish are removed effectively. When processing PET, it is possible to increase the IV to the desired level.

At NPE, Starlinger is showing the recoSTAR dynamic recycling extruder, PCUplus pellet flusher and viscoZERO melt phase decontamination reactor at their booth in the West Hall.

Closing the loop for industrial plastic packaging

Being the world market leader for machinery and process technology for woven plastic bags, Starlinger also supplies the entire machine range for this type of packaging – from tape extrusion lines and circular looms to lines for coating, printing and sack conversion. With the ground-breaking “Circular Packaging” concept the company offers the first closed-loop solution for industrial packaging made of PP or PET tape fabric such as FIBCs. “Continuous reuse of plastics in the same application is the highest form of recycling”, said Harald Neumüller, CSO of Starlinger. “That’s why we develop machines that allow our customers to re-cycle plastic scrap instead of down-cycling it. Our technologies to process used big bags made of polypropylene or PET and turn them into new ones are unique. They constitute one step on the way to move the plastic packaging industry towards circularity. We are looking forward to share our expertise with interested visitors at our booth at NPE.”

Visit Starlinger & Co GmbH at NPE from May 6 – 10, 2024: Booth W5169