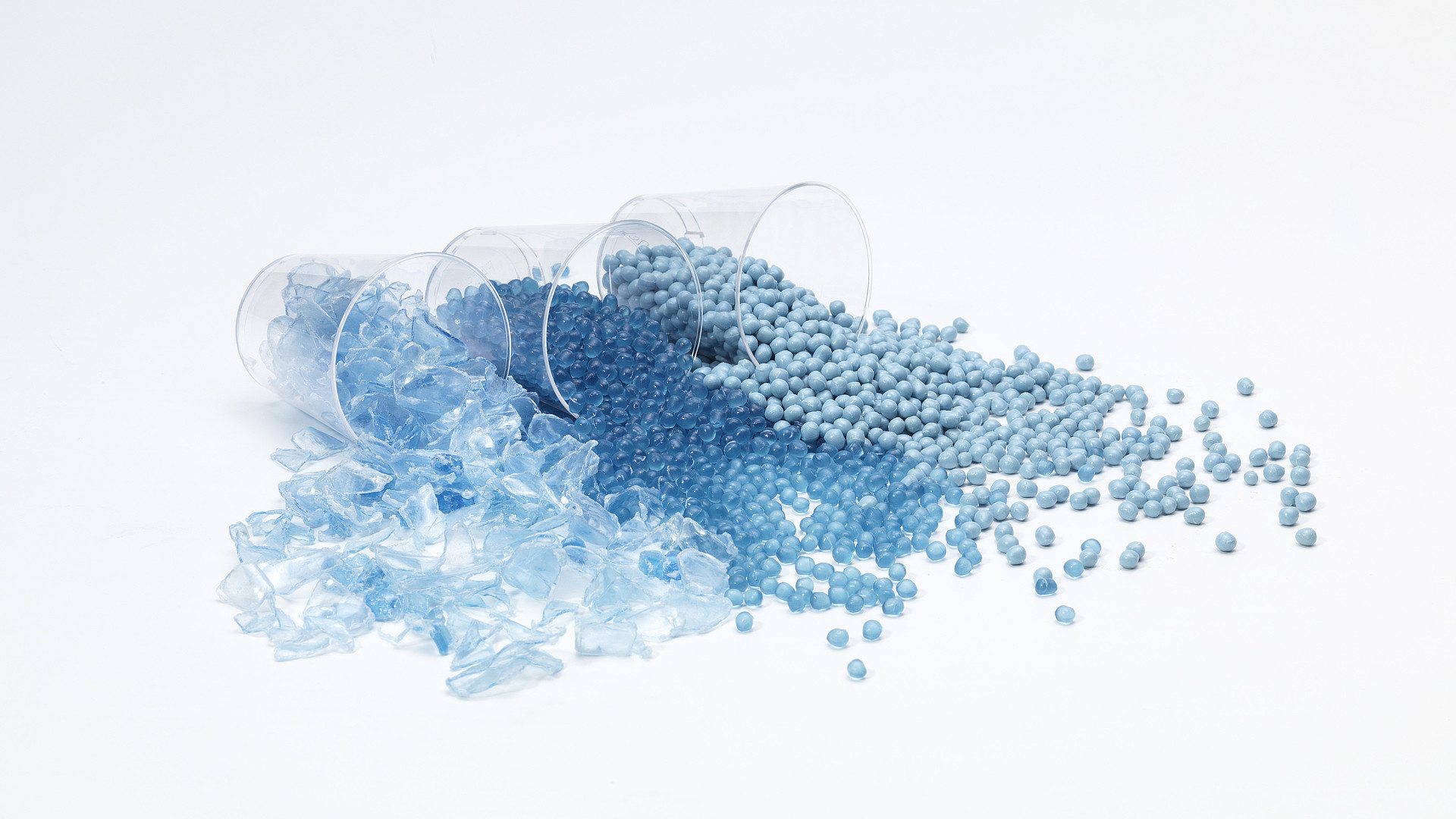

Starlinger recycling technology offers pioneering solutions for converting used plastics and plastic production scrap into an economically and ecologically significant resource.

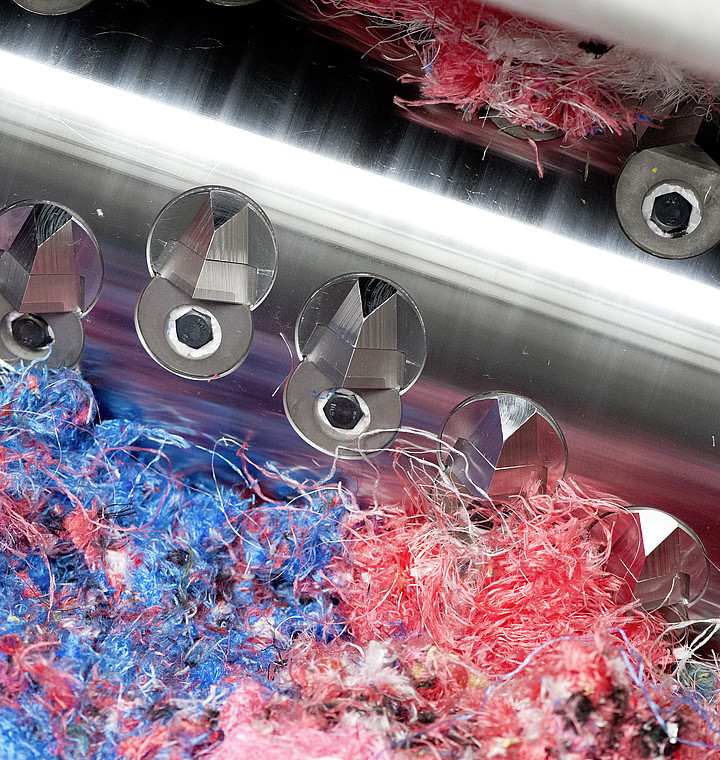

Films, PET flakes, fibers, nonwovens or woven bags: We supply state-of-the-art plastics recycling systems that transform post-industrial and post-consumer waste into a valuable secondary raw material. Sustainability concerns everyone – and requires visionaries. With our machines you become part of the ever-growing circular economy.

The recoSTAR product line

Our customers around the globe are as diverse as the requirements they place on our systems. Decades of experience in the engineering, marketing and servicing of recycling systems provide us with sound know-how that we use to develop tailor-made solutions for the varying markets. Proximity to our customers enables us to take into account different regional requirements in terms of polymers, additives, production processes, throughputs and application industries in the development of our systems.

In contact with Starlinger all over the world.

Starlinger offices and agents worldwide