Flexible bulk containers

Flexible containers made of woven fabric (FIBCs, big bags) have revolutionised dry bulk logistics in many sectors. Building materials, metal parts, chemicals, minerals, foodstuff and many other dry bulk goods can be safely and easily transported, loaded and stored in a space-saving way using FIBCs. Starlinger supplies the production technology for heavy-duty fabrics used to manufacture single- or multi-use FIBCs in various sizes and designs, as well as testing machinery for load tests on the finished container bags.

A closed packaging loop also for FIBCs

Millions of big bags are in use around the world every day. Made from woven polypropylene tapes, they have a far better CO2 balance per 1,000 litres of transported goods than rigid containers such as octabins or rigid plastic containers. Although big bags are suitable for recycling, most end up in landfill or are incinerated after one-time use. Those that are recycled are usually turned into products of inferior quality – so-called downcycling. To change this, Starlinger has launched the 'Circular Packaging' concept: A used big bag should become a big bag again. The holistic concept covers all steps in the life cycle of a big bag – from production, use and cleaning to recycling. It starts with the easy-to-recycle design of the big bags: 'Design for recycling' is the motto. Ideally, all components should be of the same material, and any PE inliners and product labels must be easy to remove. Another important part of the concept is the so-called material passport, in which every step in the lifecycle of the big bag is recorded. This ensures a homogeneous material stream and, as a result, high recyclate quality.

FIBCs made from recycled polypropylene

The new SPB filter for tape extrusion makes it possible to process high shares of rPP on Starlinger tape extrusion lines. Starlinger recoSTAR recycling lines ensure that the used big bags are recycled into high-quality regranulate so that the tape quality is not impaired and the container fabric fulfils all safety standards for FIBCs. Properties such as tensile strength, weight and safety factor of FIBCs with rPP content have been tested in certified test procedures and correspond to those of FIBCs made from virgin material.

FIBCs made from PET tape fabric – also with 100 % recycled material

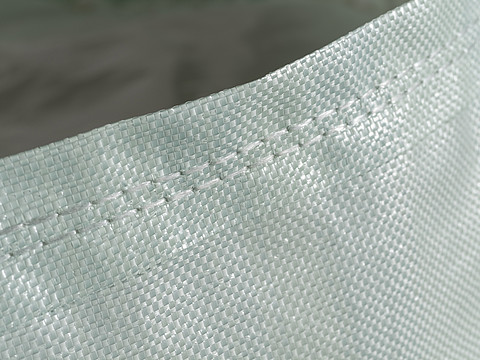

Based on many years of experience in PET recycling, Starlinger has developed the technology for producing fabric from PET tapes. PET tapes impress with high tensile strength and a high creep modulus (deformation resistance under mechanical stress), as well as low residual shrinkage values, resulting in the fabric and the products made from it having particularly high strength and long-term shape stability.

New possibilities in bulk logistics

PET FIBCs are especially suitable for packaging and storing bulk goods with strong flow characteristics: Materials with low friction between particles – for example, expanded polystyrene beads or plastic granules with added lubricants – can be filled in PET FIBCs and stored for a long time. The strength of PET tape fabric prevents bulging and subsequent tipping over of the stacked FIBCs, even with very slippery content. Due to their dimensional stability, PET FIBCs are a cost-saving alternative to more expensive packaging like cardboard octabins.

Advantages

- High fabric strength

- High creep modulus

- Long-term form stability

- Minimal bulging

- Stacking over long periods of time

- New printing methods possible

- Improved abrasion resistance

- High seam strength

- Suitable for very high or low ambient temperatures

- Infinitely recyclable

- "Bottle to bag" recycling possible (rPET-FIBC)

Applications

- High-performance FIBCs

- Suitable for hot filling

- Filling materials with low particle friction

- IBC replacement for cardboard octabins, barrels, etc.

- Sophisticated sack designs