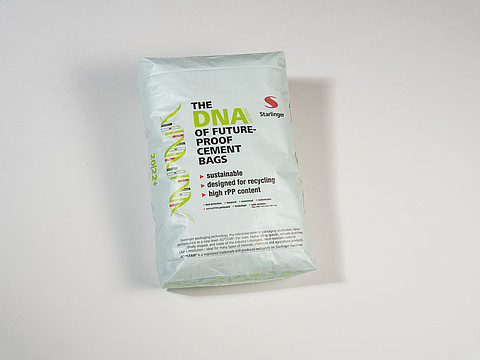

AD*STAR® – exclusively from Starlinger

AD*STAR® is the world-renowned block bottom valve sack made of coated polypropylene fabric – patented worldwide by Starlinger and produced exclusively on Starlinger machines. The sack can be designed either as a block-shaped valve sack or as an open top sack with a block bottom. It surpasses all comparable products in breaking strength, is versatile, environmentally friendly and cost-effective.

Ingenious packaging variety

In the growing packaging market for bulk goods and powdered products, AD*STAR® has proven to be an effective solution.

The original goal for AD*STAR® as a multipurpose bag concept has become a reality. AD*STAR® bags are used for all kinds of free-flowing bulk goods such as cement, building materials, fertilizers, chemicals and granules, but also for flour, sugar, and animal feed. Today, the name AD*STAR® is globally protected as a registered trademark. Since its market launch, the robust, versatile, and environmentally friendly bag has captured significant market shares: In the year 2000, around 400 million AD*STAR® bags were produced on 39 AD*STAR® conversion lines. Today, the global production capacity exceeds 30 billion AD*STAR® bags per year!

Multiskilling with AD*STAR®

With a filling volume from 9 to 75 liters, ranging from almost airtight to highly air-permeable, from extremely light to highly durable, and from industrial to consumer goods bag, AD*STAR® bags can be easily modified to meet the respective requirements.

For bulk goods that require air-permeable sack fabric, the ad*starKON conversion can be retrofitted with a microSTAR micro-perforation unit, which ensures high air permeability while preventing the escape of the contents from the bags.

AD*STAR® bags can also be made from fabric laminated with high-resolution printed BOPP film. This innovative technique opens up the market for consumer goods bags to AD*STAR® producers. This market sector for PP fabric bags is still young, but it has enormous potential – especially in industrialized countries.

Environment in the green, numbers in the black

Economical use of raw materials, extremely low breakage rate, recyclability and reusability of the bags: Environmental benefits are also economic advantages. Due to the material properties and the special manufacturing process, an AD*STAR® bag weighing just 75g can hold 50 kg of cement. A comparable 3-layer paper bag weighs about 180g, and a PE film bag 150g. The cost-conscious use of raw materials also contributes significantly to protect nature's resources.

AD*STAR® for Environment and Economy

Compared to traditional paper bags, bag breakage rates drastically reduce as soon as AD*STAR® bags are used. This not only saves money: The risk of soil and water contamination by the contents is practically zero with AD*STAR®. The potential savings in energy and materials are also enormous considering that filling, conveying, palletizing, stacking, loading, and transporting traditional paper bags usually involves a breakage rate of about 5%.

Market Value Before and After Use

The numbers above don't even account for the sack breakage that occurs with conventional bags in retail and with end consumers. That's why more and more traders and consumers specifically ask for AD*STAR®. Goods packaged in AD*STAR® bags thus represent a significant competitive advantage in the sale of your product.

AD*STAR® bags are also a valuable resource after use. Recycling is one option: The bags are made of polypropylene only and can be reprocessed into PP granulate. Another recycling method, intrusion, produces high-quality molded parts from mixed plastic waste. The bags can be burned without environmental concerns to utilize their calorific value, which is almost as high as that of heating oil. Cement plants worldwide cover up to 30% of their fuel needs with such secondary fuels. Often it doesn't come to that, as in many countries used woven plastic bags are employed for various practical purposes, such as in plant nurseries or as weather protection.

Cementing success

A practical example:

By switching from paper to AD*STAR® bags, a Tunisian cement plant was able to reduce its in-house bag breakage rate from 5% to 0.25%.

Converted to the needs of the whole of Tunisia with a cement production of around 160 million sacks per year and a price of around € 2.50 for a 50 kg sack, the switch to AD*STAR® sacks could save around 19 million EUR per year - the equivalent of 8 million sacks and around 380,000 tons of cement.

And that's not even counting the sacks that wouldn't break outside the cement works ...