Recycling line

recoSTAR direct

State-of-the-art recycling technology for the cost-effective processing of regrind with high bulk density (> 300 g/l): production and post-industrial scrap from materials such as PE, PP, PS, PA and PLA.

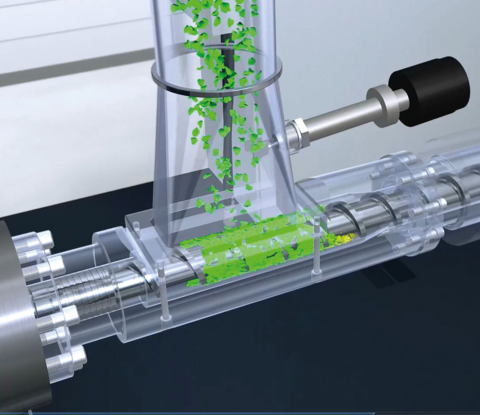

The direct feeding of the input material is done by a feeding screw mounted on top of the extruder. Additional dosing of masterbatches or additives is possible.

The user-friendly touch-screen allows simple operation with RFID chip-controlled user levels, alarm history, recipe management, maintenance control, etc. Screenshots can be downloaded via USB-port.

A variety of different melt filters for dirt particle removal are available. The optional backflushing reduces costs for filter screens and operator intervention. For higher contamination, a power backflush or continuous rotation filter is recommended.

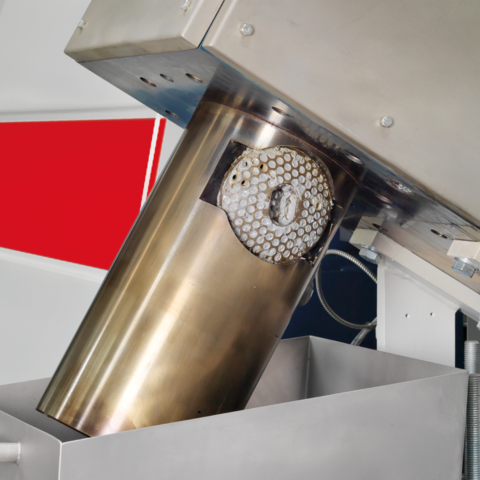

The patented water ring pelletiser ensures exact cutting for increased pellet quality and reduced wear of knives. Alternatively, strand, automatic strand, or under-water pelletisers can be used.

The produced uniform high-quality pellets have flow characteristics like virgin resin and can be reused up to 100 % in the same application or upcycled for other uses.

- for production and post-industrial scrap

- regrind with high bulk density

- wide range of thermoplastics

- space and energy saving

- one-button start/stop

- cost-effective recycling solution

Recycling line recoSTAR direct

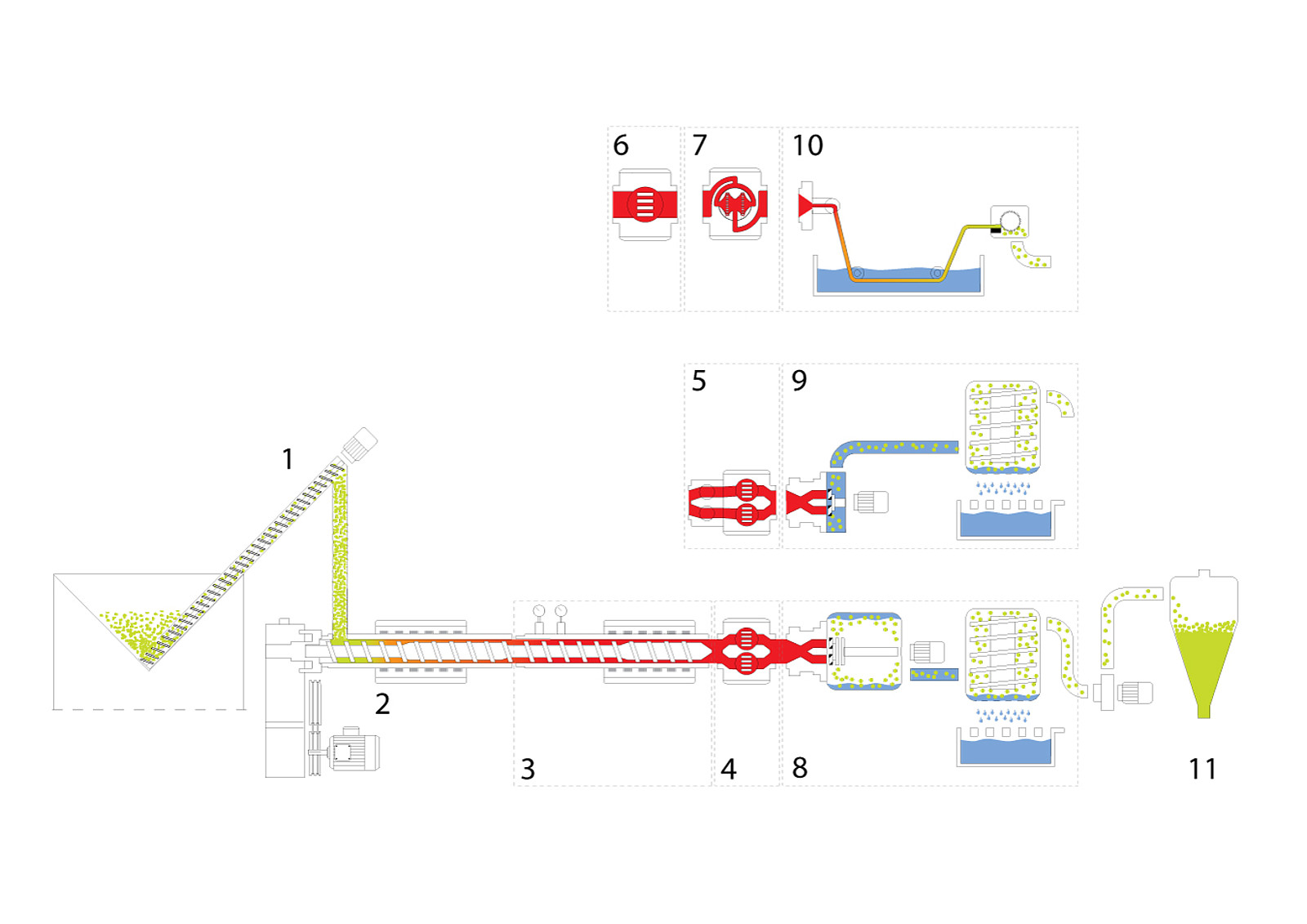

Process description

1.Hopper with feeding screw 2. Extruder 3. Venting extruder 4. Melt filter without backflush 5. Melt filter with backflush 6. Discontinuous melt filter 7.Power backflushing filter 8. Water ring pelletiser 9. Underwater pelletiser 10. (Automatic) strand pelletiser 11. Storage silo

Advantages recoSTAR direct

- Dusty regrind transformed into dust-free regranulate

- Economical investment

- Low energy consumption/kg

- Easy-to-work-with recycling solution

- Operator and maintenance friendly

- For a wide range of thermoplastics

- Advantageous processing costs